CUSTOM ROTOMOLDING

Custom Rotomolding Services

Our Goal is to provide quality parts and service.

After almost 30 years of experience manufacturing aluminium rotational molds, we have expanded our process to provide Custom Rotationally Molded Polyethylene products for a diverse selection of applications.

We have an extensive array of knowledge in new development, CAD design and tooling production.

We strive to offer consistent wall thickness, durable corners, high strength and tight tolerance quality parts and also perform in-house mold repairs as needed to obtain seemless parts.

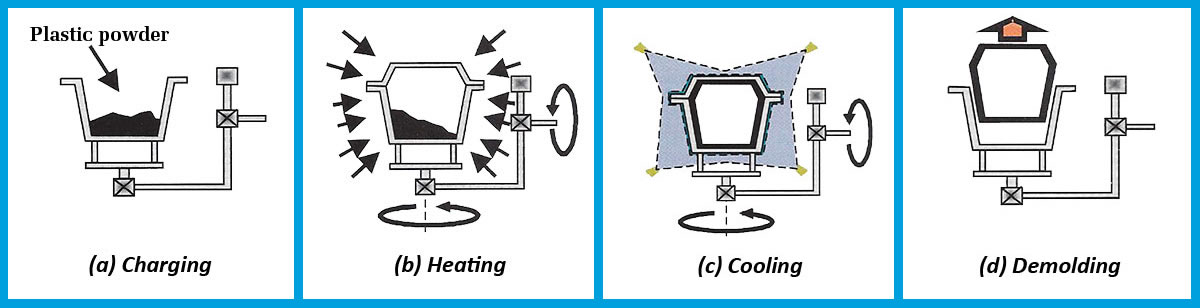

THE ROTATIONAL MOLDING PROCESS

Rotational molding, also known as rotomolding, it is the process of making hollow plastic products by placing powdered resin into a mold and rotating the mold bi-axially in an oven until the resin melts and coats the inside of the mold. The mold is then cooled and the finished product is removed from the mold.

Rotational molding utilizes various plastic materials such as Polyethylene (Linear Low Density Polyethylene LLDPE, Medium Density Polyethylene MDPE, High Density Polyethylene HDPE).